Properties

High strength & tear resistance:

silicones are strong

At low or high temperatures, silicones are stronger than other elastomers, such as natural rubber. At SILMIX®, we have access to WACKER’s HDK® pyrogenic silica, a class of specialized silica grades ideal for strengthening. Ask us about our high-strength compounds featuring outstanding tear resistance.

Temperature resistance:

silicones take the heat

Silicone rubber maintains its properties over a wide temperature range. Special products such as phenyl silicones can stay elastic at -90 °F, and heat-stabilized compounds can endure temperatures up to 450 °F. Call us to discuss how to solve your temperature issues.

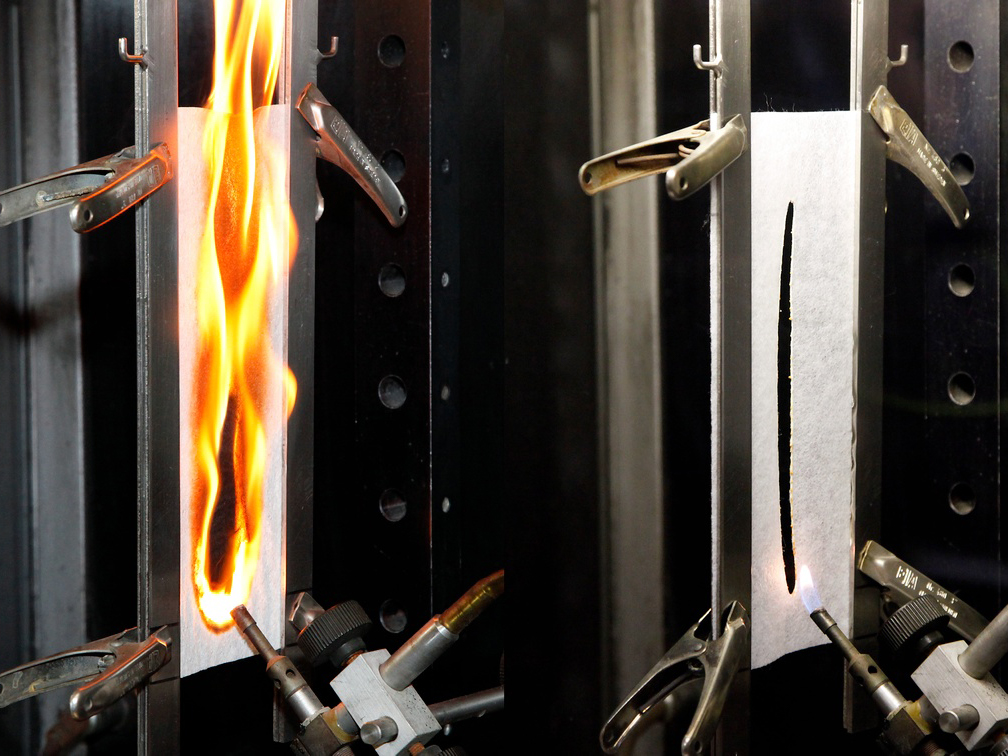

Flame resistance:

silicones add safety

Silicone rubber is flame retardant and has a flashpoint of 1382 °F and an ignition temperature of 842 °F . Silicone rubber does not produce toxic gases in the event of fire, making it applicable for safety-critical applications, such as fire safety cables for buildings, aircraft, railcars and ships. Let us show you our compounds that are compliant with UL 94 HB, UL 94 V-1, UL 94 V-0.

Chemical resistance:

silicones protect

Standard silicones are chemically inert and immune to many common acids, oxidizing chemicals, ammonia and isopropyl alcohol. Special grades are resistant to more aggressive materials. Fluorosilicones withstand hot oil and fuel, even at high temperatures. Compounds of silicone rubber and EPDM exhibit strong resistance to acids, alkalis and some solvents. Let us show you our compounds for your challenging conditions.

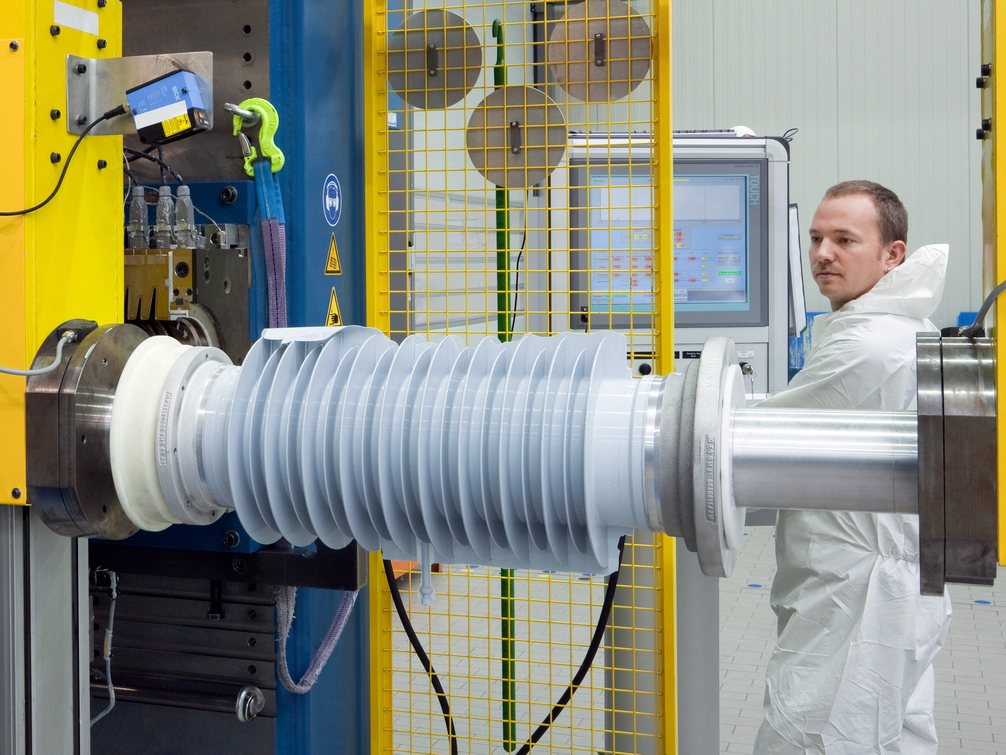

Insulating and conductive:

silicones are both

The dielectric properties of silicone compounds offer insulating properties that are stable over a wide temperature and frequency spectrum, even when exposed to humidity. Silicone compounds can become conductive or semiconductive by adding materials such as carbon or graphite.